Services

We are dedicated to the complete mechanical rebuild on the Bentleys that we are commissioned to restore.

Our long history and success at producing Race or Rally prepared cars has enabled us to use that engineering quality throughout our complete range of mechanical rebuilds.

The development on the Rally prepared Continentals has been a huge benefit and allowed us to produce Bentleys for any style of driving requirement or use.

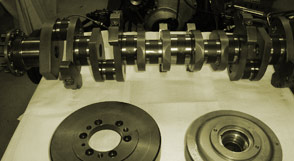

With the help of the late Christian Hueber and extensive copies of the Works Experimental Department Papers we have developed an extremely powerful engine specification. For example, with our own design of crankshaft, Fluid Damper Coupling, This means a far smoother, powerful and efficient engine than original.

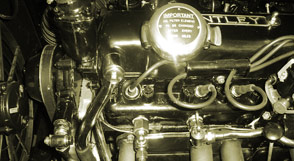

Our overall aim was to produce a higher torque engine, more power, but retain the smoothness associated with the 6 cylinder design. Added to this, where possible we have used the original Bentley throttle linkage and assemblies thus retaining the authentic attractive design.

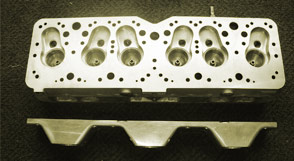

This design work has been based on the 'OPWAS' cylinder head kit that was available from Crewe in 1954 to upgrade the Continental.

We have extensively modified and gas flowed the S Type head and combustion process. This meant designing a new inlet manifold to accept the 2 inch S.U. Triple carburettor configuration.

Our new six branch exhaust systems are hand made here, after being computer designed by Christian Hueber in the U.S.

The last dynomometer engine development, tested in the summer of 2007, gave the 4.9 litre S Type Continental, the following figures:-

239 BHP @ 4500 rpm. TORQUE 340 lb ft.@ 2950 RPM The Compression Ratio was 8.6-1 This compares with the original Continental power of 158 BHP and Compression Ratio of 7.2-1 when the Continental first became available in 1952.

After producing the above power figures we have also improved other aspects of the Continentals mechanical specification as follows:-

Forged alloy pistons and Forged Alloy Steel Connecting Rods are all very finely balanced individually and as an assembly using the very latest balance methods.

The engine block is expertly gas flowed, to a high design specification. Thereby correcting the damaging combustion roughness that Rolls-Royce found with their testing in the 1950's, but were unable to track down the cause.

Hardened exhaust valve seats are fitted as standard allowing the cars to run at speed or high revs on un-leaded fuel. Top quality valve guides are machined to suit the improved design and material of our valves.

Flywheel machining, new clutches, re profiled camshafts, new push rods, and higher tensioned valve springs have all been included, to allow the engine development to be reliable and efficient.

MSD based ignition systems give a double spark during each ignition cycle, which has been far more reliable than the standard points system.

Cooling has been greatly improved by the fitting of the alloy radiator systems. The factory conversion of the higher speed water pumps for use in Switzerland, electronic fan assemblies, and the engine oil coolers are fitted into the air stream under the front wing.

All gearboxes are painstakingly rebuilt, making sure they are to latest factory specifications.

The back axles are completely rebuilt with new bearings, trunion shafts, and shims.

The back axle pinion drive keys are then upgraded, as are the centre prop-shaft bearing. The prop-shaft is also finely balanced for high speed use.

All four shock dampers have their poundage increased, and are modified to use modern seals.

The steering has been up-graded to the last factory specification figures. The cars are all fitted with Harvey-Bailey front and rear, roll bars. These are connected and fitted with our own universal rod end connectors. Ride heights are lowered in most cases and the spring poundage increased by 10%.

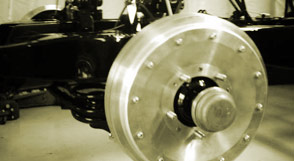

Finally, the alloy brake drums, which are an immense braking improvement over the original brake drums, are fitted along with the 6 inch wide alloy wheels. The brake shoes and drums last for hugely increased distances over the original, even with the advanced performance. The increase in the track has given the Continental better cornering speeds. This in turn has given the Continental improved straight-line stability.

The full Rally prepared Continentals have been tested to speeds over 130 m.p.h.

Once the bodies are removed and held in special jigs for bracing and support, they can be repaired and welded as required, ready to be re-united with their chassis.

The first Rally prepared Continental did 70,000 miles before the Main and Big End Bearings were changed. Taking account of the high speed and endurance use. No problems were experienced with reliability, stability, or safety.

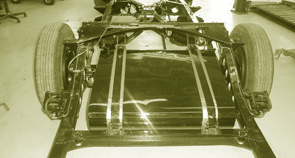

All of our chassis's are stripped right down and shot blasted. These are then given linear and diagonal measurement checks. These are welded and improved as standard work on all cars.

They are finished in a high quality Transport 2 pack enamel colour of the owner’s choice.

All of the above has been possible by using the factory tests and development data undertaken at Crewe or the Hythe Road premises. And using the late Christian Hueber’s knowledge, and our own developments here at Padgett Motor Engineers over a long time.

Our records in Bentley Motor Racing over the past 40 years with my father's design work on the Mk Vl Bentley Special sports cars, have been a great advantage to the customers Bentleys.

In this modern day expertise in material availability, and machining we have been able to, not only improve the speed and power of the Continentals, but also the efficiency and smoothness. This same standard is then carried forward to work on any Bentley.

Our customers can now use and drive any standard Bentley or Continental in the knowledge that the work undertaken, to which ever level of performance, durability, or smoothness required, the original character of these fine Continentals, and standard Bentleys is enhanced not diminished.

Links: